- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Services

- Services

- CNC Machining Services

- CNC Milling Services

- CNC Turning Services

- Laser Cutting Services

- Forging Services

- Casting Services

- Investment Casting Services

- Die Casting Services

- Stamping Services

- Deep Drawing Services

- Aluminum Extrusion Services

- Plastic Injection Services

Services

Youlin is a full service products and solutions provider of metal fabrication and plastic molding injection . Our team work closely with international customers to meet their custom manufacturing needs . We possesses over 10 years of experience in the custom CNC machining , CNC milling, CNC turning, Forging , Casting , Stamping , Deep Drawing , Aluminum Extrusion , Plastic Injection and Tube Laser Cutting business .

Manufacturing Processes

Investment casting is the process of using wax to make the mold of the parts to be cast, and then the wax mold is coated with mud, which is called clay mold. After the clay mould is dried, heat and melt the inner wax mould. Take out the clay mold after melting the wax mold and bake it into a ceramic mold. Generally, the gate system is left when making the mud mold, then the molten metal can be poured into the mold. Cool it until the part solidifies, the required parts are made.

-

CNC Machining Services

-

CNC Milling Services

-

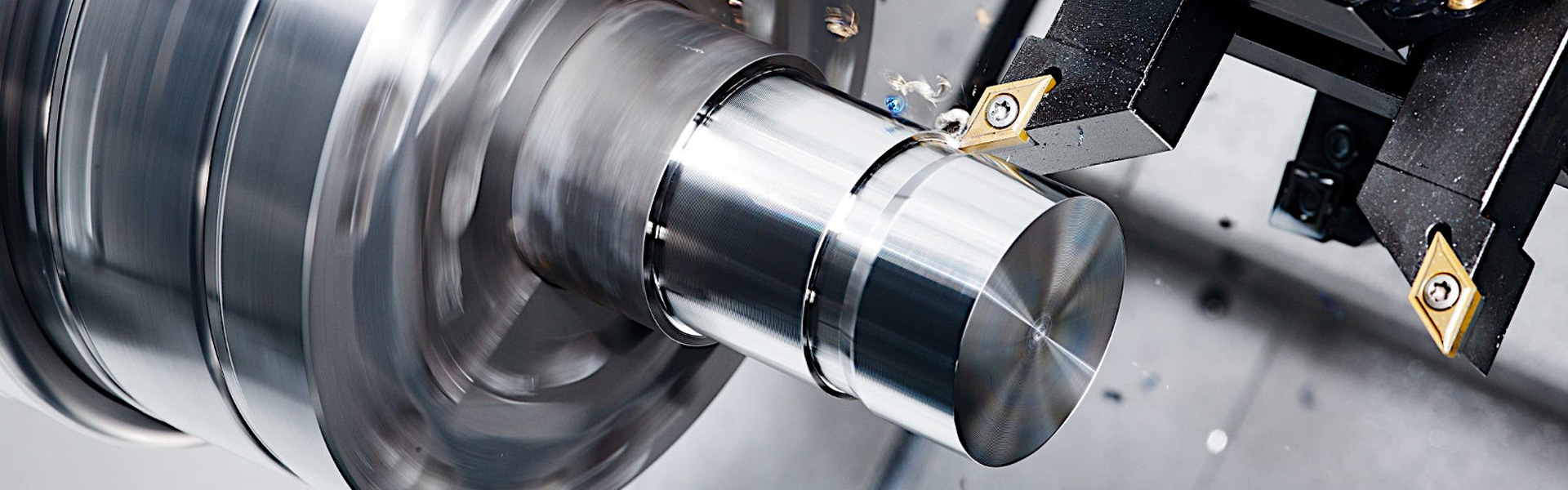

CNC Turning Services

-

Laser Cutting Services

-

Forging Services

-

Casting Services

-

Investment Casting Services

-

Die Casting Services

-

Stamping Services

-

Deep Drawing Services

-

Aluminum Extrusion Services

-

Plastic Injection Services

Related product samples :

CNC Machining Services

Milling and turning are two important operations within CNC machining. They support machining operations to ensure the construction of components with precise specifications, and with a certain type of internal or external surface. Both CNC milling and turning have sub-operations that allows for the creation of different industrial components. Youlin Manufacturing Technologies meets the component requirements of industrial customers by providing end-to-end CNC turning and milling services.

-

CNC Milling

CNC Milling -

CNC Turning

CNC Turning -

CNC Laser Cutting

CNC Laser Cutting

As a 10+ years’ experience of custom CNC Machining Parts fabricator , we can design and manufacture complex parts end-to-end using multiple tools in a single cell. We also run a comprehensive jigging system around the 4th axis so multiple quantities of parts can be machined along several planes in one setting.

Tolerances For Precision Machining

Our general tolerances for metal CNC machining parts is based on DIN-ISO-2768 Tolerances

LINEAR DIMENSIONS :

|

Permissible deviations in mm for ranges in nominal lengths |

f (fine) |

Tolerance class designation (description) |

v (very coarse) |

|

|

m (medium) |

c (coarse) |

|||

|

0.5 up to 3 |

±0.05 |

±0.1 |

±0.2 |

- |

|

over 3 up to 6 |

±0.05 |

±0.1 |

±0.3 |

±0.5 |

|

over 6 up to 30 |

±0.1 |

±0.2 |

±0.5 |

±1.0 |

|

over 30 up to 120 |

±0.15 |

±0.3 |

±0.8 |

±1.5 |

|

over 120 up to 400 |

±0.2 |

±0.5 |

±1.2 |

±2.5 |

|

over 400 up to 1000 |

±0.3 |

±0.8 |

±2.0 |

±4.0 |

|

over 1000 up to 2000 |

±0.5 |

±1.2 |

±3.0 |

±6.0 |

|

over 2000 up to 4000 |

- |

±2.0 |

±4.0 |

±8.0 |

Materials Used For CNC Machining

We work with a wide range of plastic and metal materials including aluminum, steel, stainless steel, titanium, copper, brass, bronze, plastic and many more materials .

|

Stainless Steel |

SS303 , SS304 , SS316 , SS316L , SS430 etc. |

|

Steel |

Mild Steel , Carbon Steel , 4140 , 4340 , Q235 , Q345B , 20# , 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000, C12000, C12000, C26000, C51000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Plastic |

ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek.Carbon Fiber |

|

Other |

Titanium |

Surface Finish :

|

Aluminum Parts |

Natural Anodized / Color Anodized / Sandblast Anodized / Chemical Film / Brushing / Polishing / Laser Engraving |

|

Stainless Steel Parts |

Polishing / Passivated / Sandblasting / Laser Engraving / Chroming |

|

Steel Parts |

Zinc Plating / Oxide Black / Nickel Plating / Chrome Plating / Carburized / Heat Treatment / Powder Coating |

|

Plastic Parts |

Painting / Chrome Plating / Polishing / Sandblast / Laser Engraving |

Our Equipments & Workshop :

16 Sets CNC Machining Center (4 Sets 4-axis CNC Machining Center and 12 Sets 3-axis CNC Machining Center)

12 Sets CNC Lathe Mahine

10 Sets Drilling Machine

Related product samples :

CNC Milling Services

Youlin provides a comprehensive and high-quality CNC milling service from a 3000 square meter specialist machining facility in NINGBO , China.

CNC milling parts are the most commonly used machining process . It is the process that removes the material from a workpiece by using rotary cutters . CNC milling machines are often classified by the number of axes that they have.The axis for horizontal movement are called X and Y.And the axis for vertical movement is called Z.A common milling machine often has this three axis X,Y, Z.To meet the requirement of some complex components’produce, there are now 5-axis,6-axis more common used.

Youlin is a professional CNC milling parts factory.We have 16 sets CNC milling machining centers, Some VMCs include a 4th axis attachment, allowing us to machine several faces of a part in one chucking, improving accuracy of relative location of features.Then we could reach very tight tolerances,0.005mm is possible for us.

Specializing in metals such as aluminum , brass , iron , stainless steel and titanium . We also have the capability to manufacture from various raw material types including bar stock, castings, forgings, and sheet metal. We have several coordinate measuring machines for detailed inspection.

Youlin has earned its reputation for manufacturing the highest quality custom machined parts for our customers and is committed to providing each customer with a custom solution for their application. Call today to see how we can help you.

Our Capabilities :

· Shapes: As your required

· Size range: 2-800mm diameter

· Material: Aluminum, Steel, Stainless Steel, Titanium, Brass, etc

· Tolerance: +/-0.005mm

· OEM/ODM are welcomed.

· Samples are available before mass production

Our Equipments & Workshop :

-

4 Sets 4-axis CNC Machining Center

4 Sets 4-axis CNC Machining Center -

12 Sets 3-axis CNC Machining Center

12 Sets 3-axis CNC Machining Center

Related product samples :

CNC Turning Services

Youlin is an experienced precision CNC turning supplier in China , provides the highest quality OEM CNC lathe services for customers across overseas , will meet and exceed your requirements.

We can design and make precision machined parts according to customers' samples or drawings (CAD / PDF / STP files). We can work in standard or metric dimensioning depending on your needs.

Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, titanium and plastic . With the ability to handle all of our clients’ unique manufacturing needs, from low- to high-volume production and prototyping .

Youlin offers top-notch CNC turning services for the creation of highly intricate products. Contact us today to learn more.

Our Capabilities :

·?Tolerance: Roundness and concentricity accuracy can be reached to +/-0.005mm

·?Surface roughness can be reached to Ra0.4

·?Size range: Diameter of raw material round bars from 1mm to 300mm

·?Material: Aluminum, Steel, Stainless steel, Titanium, brass, etc

·?OEM/ODM are welcomed

·?Samples are available before mass production

Our Equipments & Workshop :

-

12 Sets CNC Lathe Mahine

12 Sets CNC Lathe Mahine -

12 Sets CNC Lathe Mahine

12 Sets CNC Lathe Mahine

Related product samples :

Laser Cutting Services

We’re a professional manufacturer of metal tube fabrication in China. We provide a stable and reliable products and competitive prices for your manufacturing requirements. We will manage your manufacturing projects from materials, manufacturing, inspection, packaging to delivery whether it is low-volume prototypes or high-volume production runs.

The laser tube cutting, engraving and etching is ideal choice for processing of metal tubes surface, such as hole cutting, logo etching and pattern engraving. It is a set of laser, numerical control, precision machinery technology in one of the high-tech production process. And it direct use of three-dimensional graphics with the advantages of the no programming, edge smooth, less thermal effect, efficient and fast cutting to various of metal pipe. Applicable to all kinds of special-shaped pipe.

The Common Materials for Laser Tube Cutting, Engraving and Etching:

Materials:?Steel, Stainless Steel, Aluminum, Copper and Brass

Type: Round, Square, Rectangular, Hexagon, Oval

Related product samples :

Forging Services

FKM VITON MATERIAL

The most common forging types include hot forging and cold forging. We are main in hot forging .

The hot forging process is a forging process in which the metallic material being worked on is heated to a temperature above the crystallization temperature. This is the temperature at which the workpiece or the material is about 75% of its melting temperature. The aim of heating to such temperatures is to lower the flow stress and the pressing force required to form the required product.

Unlike cold forging, where the workpiece is worked on at room temperature, hot forging makes the metal easier to shape by heating. Therefore, it works great in the production of hard metals such as iron and its alloys. You just need to get the right hot forging temperature to increase its material ductility.

The hot forging process is pretty the same as the cold forging. The only difference is the heating of the workpiece. But the setup is basically the same. You need the material, molds or dies, and equipment to carry out hot forging. For the material, the manufacturing process can work on a vaster range compared to cold forging.

There are various types of hot forging, depending on the equipment you are using. The kind of products you are manufacturing is also another factor that determines the choice of hot forging. The most common hot forging types include free forging, roll forging, or die forging. But the most widely used type of hot forging widely used is the die forging.

Material :

|

Stainless Steel |

SS303 , SS304 , SS316 , SS316L , SS430 etc. |

|

Steel |

Mild Steel , Carbon Steel , 4140 , 4340 , Q235 , Q345B , 20# , 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Other |

Titanium |

Our Equipments & Workshop :

Related product samples :

Casting Services

We provide a variety of metal casting processes , including: sand casting , investment casting and die casting.

Sand Casting

Sand casting is used to produce a wide variety of metal components with complex geometries. These parts can vary greatly in size and weight, ranging from a couple ounces to several tons. Some smaller sand cast parts include components as gears, pulleys, crankshafts, connecting rods, and propellers. Larger applications include housings for large equipment and heavy machine bases. Sand casting is also common in producing automobile components, such as engine blocks, engine manifolds, cylinder heads, and transmission cases.

The four most common materials that are used in sand casting is aluminum alloys , brass alloys , cast iron , cast steel .

The Process of Sand Casting

We support 3 kinds of sand casting techniques :

Green Sand Casting

The green sand is basically a wet mixture of sand and clay, no chemical is added. The sand mold is squeezed together and holds its shape. The choice of sand has a lot to do with the temperature at which the metal is poured. At the temperatures that copper and iron are poured, the clay gets inactivated by the heat, which is a non-expanding clay. So instead, those that pour iron typically work with silica sand that is inexpensive compared to the other sands.?

Resin-bond Sand Casting

Resin binders are natural or synthetic high melting point?gums. There are also cold-set resins, which use a?catalyst?instead of a heat to cure the binder. Resin binders are quite popular because different properties can be achieved by mixing with various additives. Other advantages include good collapsibility, low gassing, and they leave a good surface finish on the casting.?

Shell Mold Casting

Shell mold casting process offers better surface finish, better dimensional tolerances, and higher throughput due to reduced cycle times. The materials that can be used with this process are cast irons, and aluminum and copper alloys. The shell molding process produces cost savings solutions for difficult shapes, pressure vessels, weight sensitive parts, and castings requiring superior surface finishes.

Related product samples :

Investment Casting Services

Investment Casting is also known as Lost Wax Casting is generally used for small castings are made from almost any metal, especially stainless steel. This process generally more expensive per unit than die casting or sand casting but with lower tooling cost. It can produce complicated shapes that would be difficult or impossible by normal manufacturing techniques. Parts made with investment castings often do not require any further machining, because of the close tolerances that can be achieved.

Steps of Investment Casting Process :

Investment casting is the process of using wax to make the mold of the parts to be cast, and then the wax mold is coated with mud, which is called clay mold. After the clay mould is dried, heat and melt the inner wax mould. Take out the clay mold after melting the wax mold and bake it into a ceramic mold. Generally, the gate system is left when making the mud mold, then the molten metal can be poured into the mold. Cool it until the part solidifies, the required parts are made.

Our Equipments & Workshop :

Related product samples :

Die Casting Services

Die casting is used to produce zinc and aluminum parts, by injecting molten material – under high pressure – into reusable steel molds . They can be designed to produce very complicated parts with pin point accuracy. Our die casting parts with sharp definition, strong material integrity and smooth or textured surface finishes. Our die casting parts are application for the following industries: Automotive, Agricultural, Commercial Vehicle, Heavy Equipment, Off-Highway and Recreational Vehicles.

Material :

Aluminum Die Castings Materials: A356 / A360 / A380 / ADC-12 / ADC-14 etc.

Zinc Die Castings Materials: ZA3 / ZA8 / ZA12 / ZA27 etc.

Our Equipments & Workshop :

Related product samples :

Stamping Services

Youlin specializes in custom precision metal stampings for complex, high precision parts for the aerospace, chemical, automotive, electronics, marine and musical instrument industries.

Our metal stampings are produced from a wide spectrum of materials, which include cold rolled steel, stainless steel, draw quality steel, brass, aluminum, copper, plastic, and high strength materials.

We work with materials that range in thickness from .005″ (0.13 mm) up to .5” (13 mm) and with configurations that range from the simplest of designs to complex in nature. These varying factors to the selection of our numerous punch presses for production. We are also capable of handling coils up to 45” (1143 mm) in width.

Press capacities range from 32-ton to 350-ton Mechanical Presses and from 300-ton to 800-ton Hydraulic Presses. Our recent expansion of new hydraulic and straight side presses have given us even greater flexibility when choosing the most appropriate equipment to manufacture the required specs to your application needs.

Our Advantages :

Lower Part Costs:?More parts per hour can be produced. Our presses use material more efficiently

Lower Tooling Costs:?More processes are done in fewer operations = smaller and less expensive tools

More Precise Parts Can Now Be Stamped:?Parts that used to require laser, wire or water cutting can now be stamped

Take Over More of Your Existing Tooling:?More bed sizes, speeds and drawing options. Our presses extend the life of your old tooling

Improved Drawing & Forming:?Fewer hits = less time and less expensive tools.

Our Equipments & Workshop :

4 Sets 16 Tons Stamping Machine

2 Sets 40 Tons Stamping Machine

2 Sets 60 Tons Stamping Machine

1 Set 100 Tons Stamping Machine

1 Set 150 Tons Stamping Machine

1 Set 45 Tons Hydraulic Press

1 Set 100 Tons Hydraulic Press

1 Set 200 Tons Hydraulic Press

Related product samples :

Deep Drawing Services

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch . It is thus a shape transformation process with material retention. Youlin provides a high quality affordable deep drawn stamping service according to customer requirements or drawings. We have experience with metal stamping with normal stamping dies, compound dies and progressive dies. Our own engineering team to designs stamping molds in-house.

Material :

|

Aluminum |

AA1060 / AA3003 / AA5052 / AA6061 / AA7072 etc. |

|

Stainless Steel |

SS201 / SS202 / SS304 / SS316 / SS316L etc. |

|

Brass & Copper |

C27000 / C28000 |

|

Steel |

Carbon Steel / Cold Rolled Steel / Mill Steel etc. |

Our Capabilities :

·?Length/width/diameter up to 1.2 meters

·?Height up to 500 mm

·?Wall thickness up to 10 mm

·?Tolerance ±0.2 mm or less

Our Equipments & Workshop :

4 Sets 16 Tons Stamping Machine

2 Sets 40 Tons Stamping Machine

2 Sets 60 Tons Stamping Machine

1 Set 100 Tons Stamping Machine

1 Set 150 Tons Stamping Machine

1 Set 45 Tons Hydraulic Press

1 Set 100 Tons Hydraulic Press

1 Set 200 Tons Hydraulic Press

Related product samples :

Aluminum Extrusion Services

We specialize in manufacturing aluminum profiles and custom aluminum parts to many industrial groups. Our past clients include building & construction, automotive, electronics, agricultural, new energy companies and many other manufacturing companies.

Our extruded aluminum shapes include standard aluminum extrusions such as aluminum round tubes, square tubes, aluminum flat bars, aluminum angles and channels, aluminum window & door profiles, extruded heat sinks, aluminum T-slot frames, motor housings and custom aluminum shapes.

We also provide extensive and varied range of processing services including precise cutting, custom CNC machining, bending, pressing and welding fabrication based on extruded aluminum. When it comes to final surface finishing such as aluminum anodizing and powder coat, we can produce high quality aluminum products to meet our clients' specifications thanks to our in-house finishing processes. our aluminum CNC machined parts and custom fabricated components are widely used in applications including furniture frames, auto spare parts, air conditioners, LED lighting enclosures, motor housing, conveyor systems, heat sinks, framings and brackets for solar panels, electrical machinery and equipment, medical equipment, sports equipment.

Our Equipments & Workshop :

Related product samples :

Plastic Injection Services

Youlin specializes in plastic injection molding in China to produce a wide variety of plastic injection molding products from high-tech parts with very tight tolerances including electronic enclosures as well as industrial and consumer products .

For over 15 years we've provided our customers with quality products and value-added services, we've grown up in the industry applying a hands-on approach to precision injection molding. We offer complete project management services that leverage our years of experience manufacturing products for a wide array of applications. This vast knowledge base allows us to make materials selection, facilitate parts sourcing, as well as complete product development, engineering, and mold making.

Our facility is equipped with a clean room environment and advanced electric injection molding equipment, delivering 45 to 600 tons of pressure, in shot sizes from 1 to 36 ounces, all to tolerances of ±.001”. In addition, we can also provide complete assembly services, including printing, painting, welding, and, machining.

From 2 parts to 2 million parts, we possess the production capabilities and services that will meet your product's needs. The Youlin production facility operates on a 24-hour schedule, we offer rush services, and lights out manufacturing, and provide logistical support .

Material :

●PVC ●HDPE ●LDPE ●ABS ●TPE ●Acrylic

●PC ●PP ●PS ●Nylon ●Acetal ●SAN

Our Equipments & Workshop :