- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

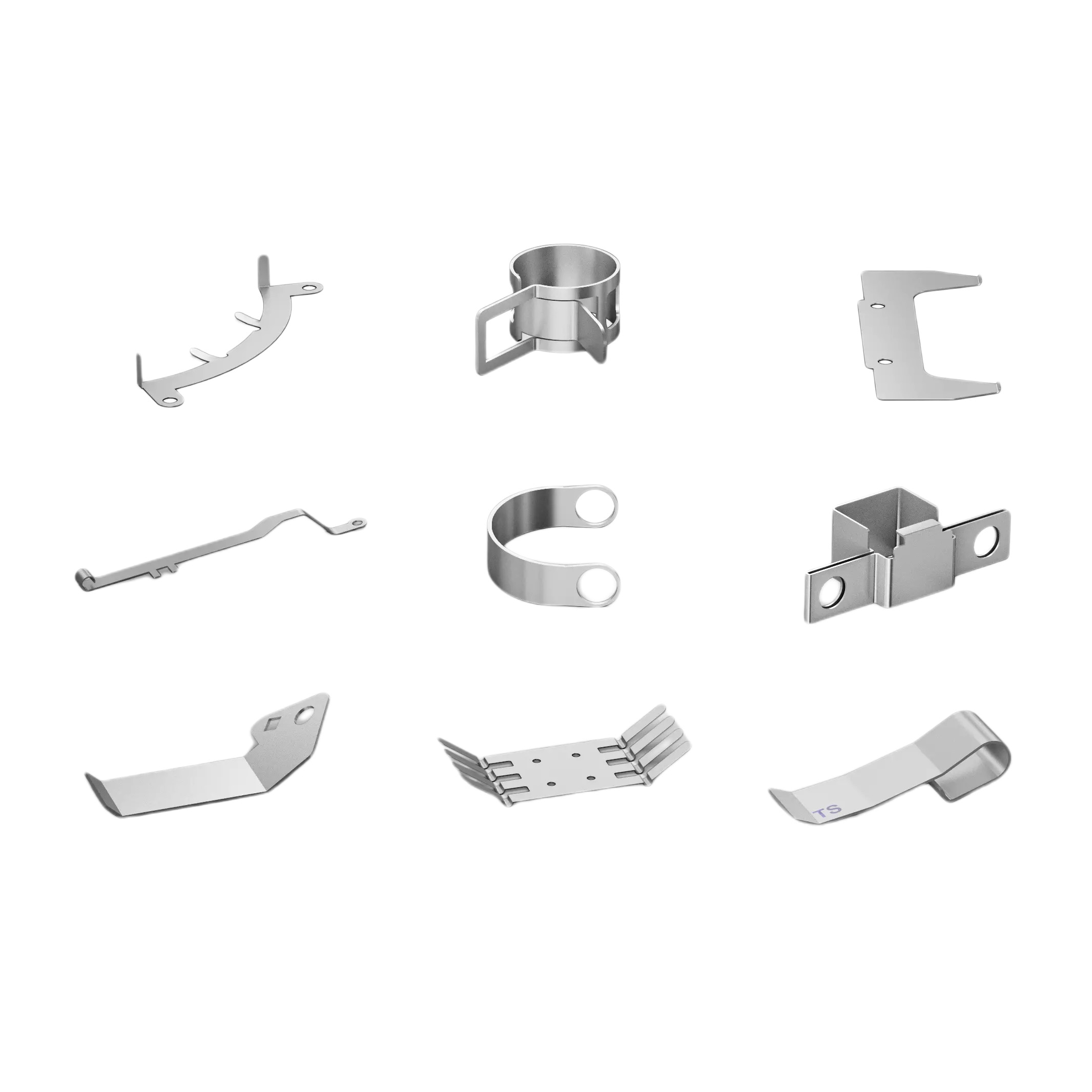

Metal Stamping Parts

At Youlin, we offer high quality, custom precision Youlin® metal stamping parts and components in many industries including Aerospace, Electronics, and Medical. We start with a custom design for your project, accounting for even the smallest features and tightest tolerances, and build stamping dies in-house. We will ensure that your part will be manufactured to your exact specifications and to the highest quality standards.

Send Inquiry

1.Precision Sheet Metal Fabrication Capabilities for Metal Stamping Parts

Our full-service custom sheet metal stamping and fabrication shop offers the full spectrum options of Youlin® metal stamping parts such as:

◆Blanking: A fabrication process where a punch and die are used to cut pieces, referred to as blanks, from sheet metal for further processing. It produces minimal burrs, which helps reduce finishing costs and lead time.

◆Piercing: Uses similar machinery as blanking and involves using a punch and die to create holes, slots, and notches in sheet metal. It creates tight tolerances, produces a cleaner cut than drilling, and is more productive than laser cutting.

◆Forming: Includes different processes where force is applied to sheet metal to modify its geometry and create thin, flat pieces that can then be formed into more complex shapes.

◆Drawing: A process where tensile force is used to stretch, or draw, sheet metal blanks over a die until the desired thickness and shape is achieved. This precision metal stamping process is used to create fluid handling, aircraft parts, electronic components, and more.

We have small punch presses for small precision Youlin® metal stamping parts, along with large punch presses for more complex custom metal stamping projects. Our metal stamping professionals are trained extensively in the metal stamping industry. Contact us today to learn more about our custom sheet metal stamping capabilities.

2.Our Competitive Advantages of Metal Stamping Parts

Competitive Pricing

Competitive Pricing

We know you need to keep your project in-budget. Our competitive pricing structure is designed to be affordable for companies of all sizes with or without limited resources.

On-Time Production

On-Time Production

Your deadlines are as important as ours. We create open communication and on-time production of your order, so you know exactly when to expect your parts.

Superior Customer Service

Superior Customer Service

Our experienced engineers and technicians are available to answer your questions and offer personalized service to help ensure you get the right parts for your needs.

Dependability and Expertise

Dependability and Expertise

We're proud to offer dependable, quality service that you can trust will meet your exact specifications each and every time.

Precision Parts on Production Runs Large & Small

Precision Parts on Production Runs Large & Small

Our team is extremely knowledgeable in the industry technology that allows for ultimate design flexibility based on your predefined project criteria.

3.Materials for Metal Stamping Parts

Our stock thickness for our ferrous and non-ferrous metals ranges from .0015 to .25+ and the stock width ranges from 1/32" to 48" with pre-plated and finishing options. We also work with a complete range of materials to offer customers a large choice in specifications, including:

✔Steel ✔Aluminum ✔Stainless Steel ✔Copper ✔Brass ✔Specialty Metals

4.Laser Cutting, Welding, and Other Secondary Services

In addition to custom Youlin® metal stamping parts, we offer a range of other sheet metal fabrication services to give our customers high precision parts, components, and assemblies that match their application requirements. We provide precision sheet metal fabrication, laser cutting, welding, secondary machining, and more.

5.Applications of Metal Stamping Parts

-

STAMPING PARTS FOR CONNECTOR

-

STAMPING PARTS FOR SHELL

-

STAMPING PARTS FOR FRAME

-

STAMPING PARTS FOR CONNECT TRIP

-

STAMPING PARTS FOR ELECTRONICS

-

STAMPING PARTS FOR TERMINAL

6.FAQ

Q: What are your types of precision metal stampings?

A: There are three basic types of precision metal stampings:

1.Progressive Die Metal Stampings

2.Deep Drawn Metal Stampings

3.Multi-Slide Metal Stampings

Q: What are metal stamping dies made of?

A: A stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile. The die's cutting and forming sections typically are made from special types of hardenable steel called tool steel.

Q: What is the meaning metal stamping?

A: Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few